"Animal protein is difficult to replace with alternative protein"

Anja WagemansProfession:

PhD in food technology

Position:

Professor (W3) at the Chair of Food Technology at the Technical University of Dresden (formerly junior professor at the TU Berlin)

Profession:

PhD in food technology

Position:

Professor (W3) at the Chair of Food Technology at the Technical University of Dresden (formerly junior professor at the TU Berlin)

Anja Wagemans wants to give meat substitute products more "bite". To this end, the food technologist is working on the structure formation of alternative plant-based and microbiological biopolymers.

Even if meat substitutes made from soya or wheat usually have a convincing flavour, they often cannot keep up with the animal original in terms of texture and mouthfeel. As a junior professor at TU Berlin, food technologist Anja Wagemans has spent many years researching the structure formation of alternative plant-based and microbiological biopolymers in order to give vegan alternatives more "bite". In an effort to put the results of her research into practice, she also works with companies involved in the development of cell-based foods. Last year, Anja Wagemans was honoured for her research work with the Young Scientist Award of the Berlin Science Prize. The researcher will now contribute her expertise to the Chair of Food Technology at TU Dresden.

What are currently the biggest obstacles in the development of innovative foods such as meat substitutes?

Animal protein (myofibrillar protein) is very functional and is very difficult to replace with alternative sources such as vegetable proteins and carbohydrates, as these differ greatly in their shape, size and properties. In terms of flavour, we therefore cannot match the original products. For this reason, it would be important to think in terms of "novel products" rather than "substitute products" and to market them accordingly. Unfortunately, the majority of consumers are attracted by familiar products, which is why a lot of persuasion and educational work needs to be done here. For this reason, many efforts are currently being made in the direction of "substitute products".

Meat substitutes cannot yet match the sensory properties of the original animal product. How can these sensory experiences of meat consumption be transferred to substitute products?

We are trying to build up the structure of meat, which is highly hierarchical from the molecular to the macroscopic level, even in less structured proteins such as globular plant proteins. This requires, for example, the addition of certain ingredients or the use of structuring processes such as extrusion or 3D printing.

What composition is important here? What role does the structure of plant proteins play?

As most plant proteins are not as functional as animal meat proteins due to their globular – i.e. spherical – structure, gelling and thickening agents are often added. This leads to a longer list of ingredients, which is often associated with a negative connotation. However, these are often only modified starch or dietary fibres.

How can parameters such as texture and mouthfeel be measured?

There are many efforts to describe sensory perceptions using instrumentally measurable variables. Simple sensory attributes such as "hardness" and "elasticity" can already be described well by measured variables. For complex sensory perceptions such as "tenderness", it is still necessary to better understand what happens structurally in the mouth and how this can be recorded instrumentally.

You have been working with companies for years on various research projects to develop innovative foods – including cultured meat.

What is the aim of the project and where do you see the challenges in the development of so-called cell-based meat?

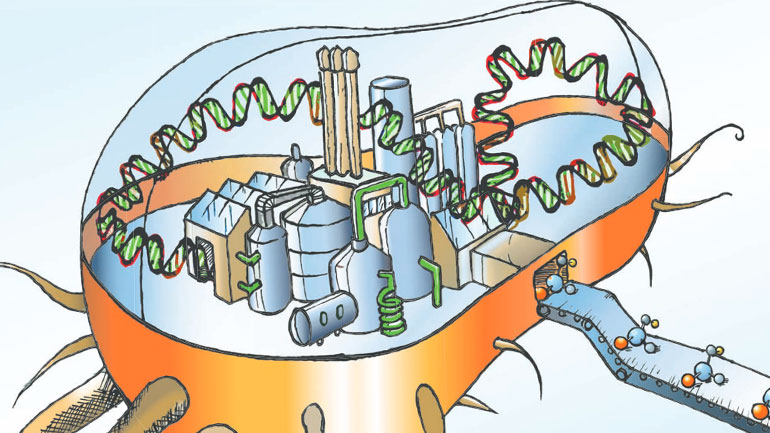

The aim of the project is to produce vegan carrier structures for cultured meat from plant proteins and alginate using a top-down approach (extrusion) and a bottom-up approach (3D bioprinting). The aim is to create new products that contain both plant components and animal cells. I see a major challenge in the fact that meat cells have to be cultivated under sterile conditions, which is difficult to realise on an industrial scale. In addition, the differentiation and cultivation of fat, meat and connective tissue cells is very complex. However, I am confident that solutions to these problems will be found.

Interview: Beatrix Boldt